Introduction

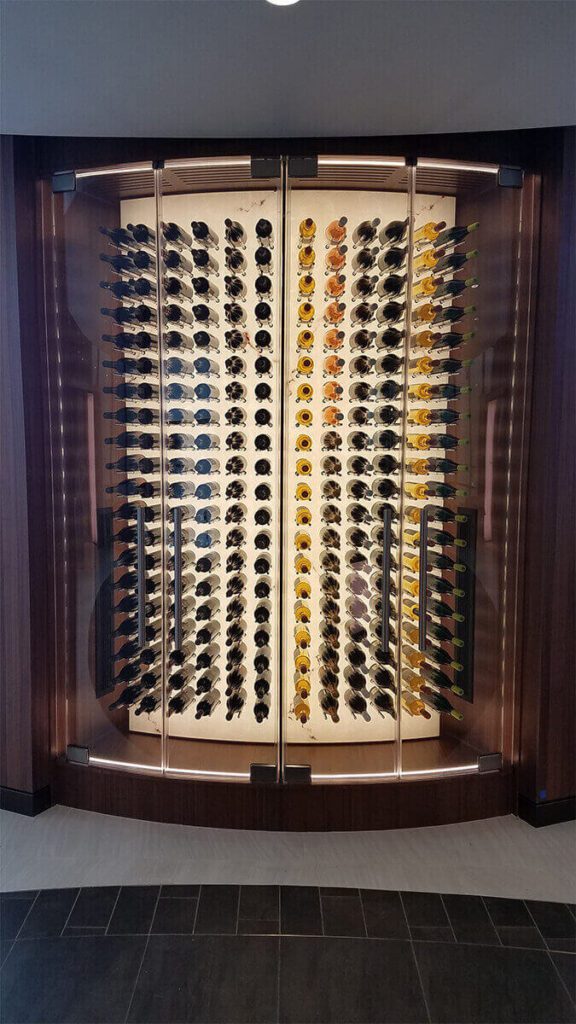

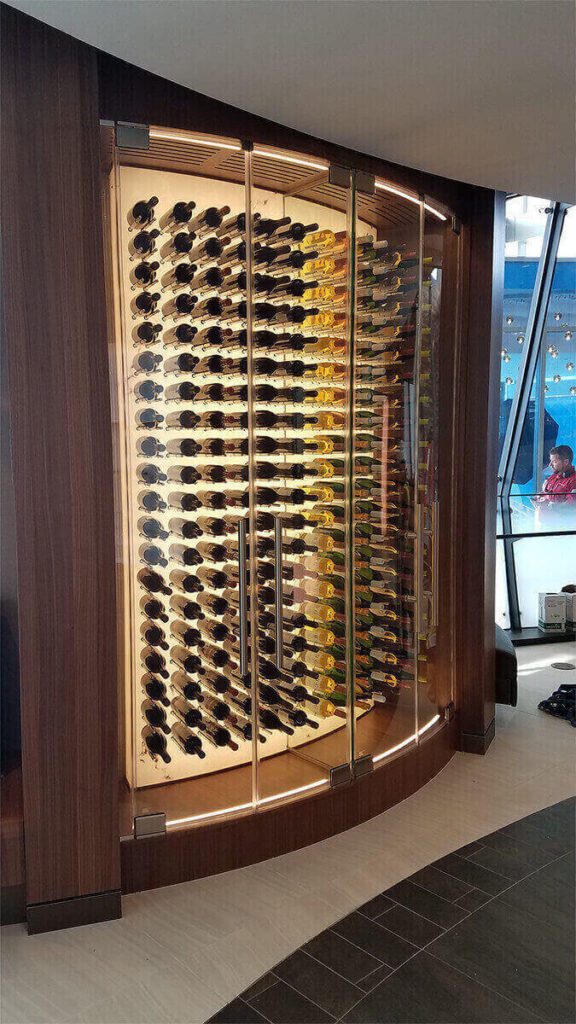

Delta Air Lines approached Vineyard Wine Cellars with an audacious vision. The airline wanted a wine wall feature to be at the heart of a 9,000-square-foot Delta Sky Club being added to a new terminal at Austin-Bergstrom International Airport. The custom glass tower would display approximately 200 bottles of wine—red and white vintages—and be able to maintain both storage and serving temperatures.

Challenges

In order to provide a sophisticated experience for travelers, the wine tower would be the centerpiece of an elevated floating Delta Sky Club. The open-concept design meant the lounge would have no ceiling or walls. The curved, modern wine feature would be displayed near the bar, surrounded by custom walnut millwork and backlit wall panels. When presented with the renderings, Vineyard Wine Cellars identified one primary and significant obstacle: the lack of mechanical space.

Racking over 200 bottles of wine and maintaining two distinct temperature- and humidity-controlled zones requires adequate space to execute. The glass wine tower did not have a ceiling. Furthermore, there was no usable space behind the tower, because it was adjacent to a glass elevator. Incorporating the necessary cooling equipment—including supply and return ventilation—and configuring the necessary ductwork into a seemingly non-existent space, without spoiling the ambiance, would require some ingenuity.

Ultimately, Vineyard Wine Cellars was tasked with integrating a refrigeration solution within the parameters of the tower blueprint. The ductwork would have to be thoughtfully incorporated into the millwork.

Finally, the cooling system would need to maintain two distinct environments within the same glass enclosure for storing red wine and serving temperatures for whites. This meant finding space for not one but two refrigeration systems within the space constraints.

The Solution

Vineyard Wine Cellars selected a Wine Guardian fully ducted system to execute the Delta Sky Lounge project. The self-contained unit is ideal for cooling smaller spaces comprising a lot of glass and is engineered to meet the demands of even the most complex applications. Along with its collaborators, CBRE and Holder Construction, Vineyard Wine Cellars set out to install the cooling solution powerful enough to maintain a pristine environment for the vintages, without jeopardizing the aesthetic of the glass wine tower.

First, the team designed and constructed custom wells above the wine tower so there was a location to unobtrusively install the refrigeration units. Running ductwork through such an exposed space also required special consideration. The Wine Guardian unit’s multi-panel design made it possible to run the supply and return between the enclosure and the open concourse.

Next, the team designed custom chases into the millwork to support airflow. Careful consideration was given to the amount of airflow required, separation of supply and return within the enclosure, and length of duct runs.

Last was figuring out how to maintain two temperatures within the tower. Delta Master Sommelier’s curated collection of red and white wines were separated by a glass partition, each zone equipped with its own Wine Guardian cooling unit set to an appropriate temperature and humidity levels and managed remotely.

The Delta Sky Lounge was designed to provide an elegant, relaxing experience for travelers going through Austin, Texas. Vineyard Wine Cellars, and its partners, is proud to have partnered with Delta Air Lines to help achieve their goal of delivering sophistication and functionality through the glass wine tower.

Results

- Two Wine Guardian D025 units

- One for collection of reds at storing temperature

- One for white vintages cooled to serving temperature

- Each 60Hz units unit delivers a maximum of 3,300 BTUs per hour

- Self-contained ducted systems

- Units installed in custom-built ceiling wells

- Glass partition separating dual zones

- Custom-designed millwork concealed the ductwork

- Remote user interface control system

- Removable control panel for easy access

- Multiple supply-air openings for installation flexibility

- High static pressure fans for extended lengths of ductwork

- Lightweight, corrosion resistant, all-aluminum exterior

“We are grateful to have had the versatility of the Wine Guardian self-contained systems and the expertise of Wine Guardian engineers to work through complex solutions such as the one implemented for Delta.” Sarah Palmer, Vineyard Wine Cellars